The Advantages And Applications Of Laser Cutting Technology

The Advantages and Applications of Laser Cutting Technology

Laser cutting technology has revolutionized the metal fabrication industry, offering precision, speed, and versatility that are unmatched by traditional cutting methods. Qingdao TianHua YiHe Foundry Factory is at the forefront of this technological advancement, utilizing state-of-the-art laser cutting machinery to deliver high-quality products and services. In this article, we will explore the advantages and applications of laser cutting technology.

1. Precision and Accuracy

High-Quality Cuts

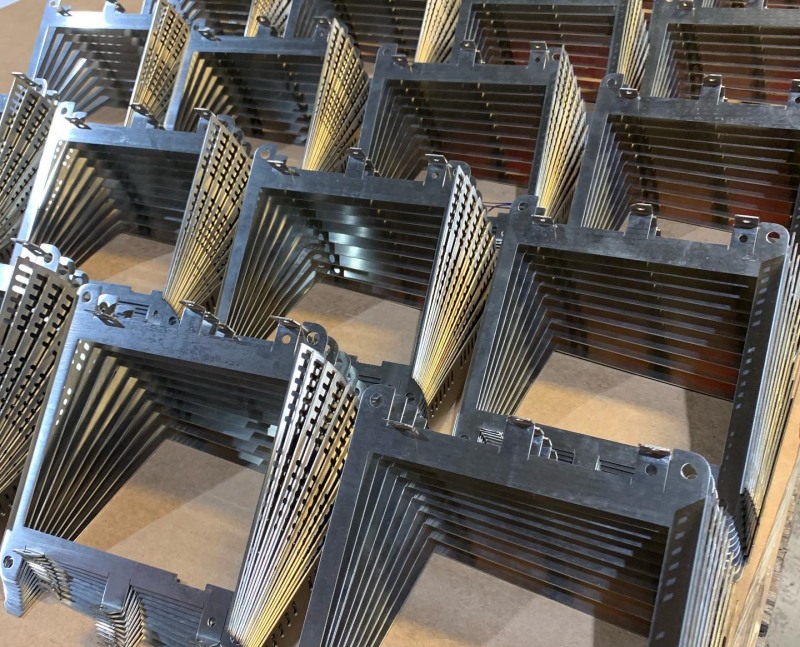

Laser cutting technology provides unparalleled precision and accuracy. The focused laser beam can cut intricate shapes and fine details with minimal kerf, resulting in clean, smooth edges. This level of precision is crucial for applications requiring tight tolerances and high-quality finishes.

Consistency

At Qingdao TianHua YiHe Foundry Factory, our laser cutting machines are equipped with advanced control systems that ensure consistent quality across multiple pieces. This consistency is essential for mass production and projects where uniformity is critical.

2. Speed and Efficiency

Faster Production Times

Laser cutting is significantly faster than traditional cutting methods. The high speed of the laser beam allows for rapid cutting of materials, reducing production times and increasing overall efficiency. This speed is particularly beneficial for large-scale projects with tight deadlines.

Reduced Downtime

Our laser cutting technology at Qingdao TianHua YiHe Foundry Factory minimizes downtime by offering quick setup times and automated processes. This efficiency translates to lower production costs and faster turnaround times for our clients.

3. Versatility

Wide Range of Materials

Laser cutting is highly versatile and can be used on a variety of materials, including metals, plastics, wood, and more. Whether you need to cut steel, aluminum, or acrylic, our laser cutting services can accommodate your requirements.

Complex Designs

The flexibility of laser cutting technology allows for the creation of complex designs that would be difficult or impossible with traditional cutting methods. This versatility opens up new possibilities for innovative product designs and applications.

4. Cost-Effectiveness

Reduced Material Waste

Laser cutting is a contactless process, which means there is minimal tool wear and reduced material waste. The precision of the laser beam allows for optimal material utilization, lowering overall production costs.

Lower Labor Costs

The automation capabilities of our laser cutting machines at Qingdao TianHua YiHe Foundry Factory reduce the need for manual labor, resulting in lower labor costs. The efficiency of the process also means fewer errors and less rework, further reducing expenses.

5. Environmental Benefits

Energy Efficiency

Laser cutting technology is more energy-efficient compared to traditional cutting methods. The concentrated laser beam requires less power to cut through materials, reducing energy consumption and lowering the carbon footprint of the manufacturing process.

Clean Process

Laser cutting produces fewer pollutants and less noise than mechanical cutting methods. This cleaner process contributes to a safer and more environmentally friendly workplace.

Applications of Laser Cutting Technology

Automotive Industry

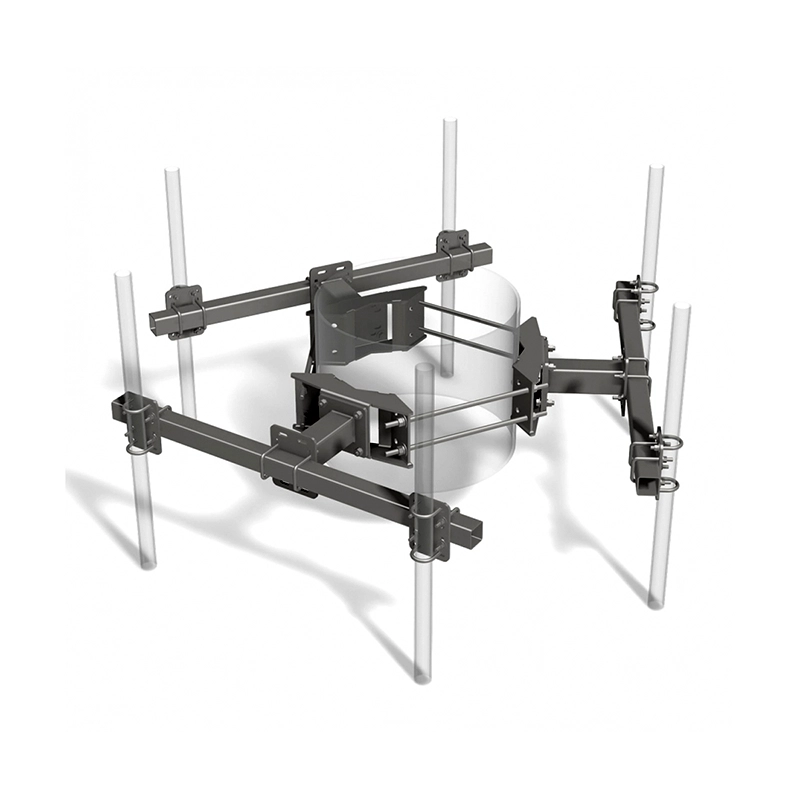

Laser cutting is widely used in the automotive industry for cutting metal parts, body panels, and intricate components. The precision and speed of laser cutting ensure high-quality parts that meet stringent industry standards.

Aerospace Industry

In the aerospace industry, laser cutting is employed to manufacture complex components with tight tolerances. The ability to cut lightweight materials like aluminum and titanium makes it ideal for producing parts that require both strength and reduced weight.

Electronics Industry

The electronics industry benefits from laser cutting technology for creating precise and intricate components, such as circuit boards and enclosures. The accuracy of laser cutting ensures that these components fit perfectly and function reliably.

Construction Industry

Laser cutting is used in the construction industry for fabricating structural components, decorative elements, and customized metal parts. The versatility of laser cutting allows for the creation of unique designs and intricate details in architectural projects.

Medical Industry

In the medical industry, laser cutting is used to produce surgical instruments, implants, and other medical devices. The precision and cleanliness of the laser cutting process are essential for creating high-quality, sterile products.

Conclusion

Laser cutting technology offers numerous advantages, including precision, speed, versatility, cost-effectiveness, and environmental benefits. At Qingdao TianHua YiHe Foundry Factory, we leverage these advantages to deliver top-quality products and services to our clients across various industries. Whether you need intricate metal parts or complex designs, our laser cutting capabilities can meet your fabrication needs. Contact us today to learn more about how our laser cutting services can benefit your next project.