Understanding the Importance of Precision in Metal Fabrication

Metal fabrication is an essential process in manufacturing, playing a critical role in the production of a wide range of products, from industrial machinery to consumer electronics. The success of these products often hinges on the precision with which metal parts are fabricated. In this article, we will delve into the importance of precision in metal fabrication, exploring its impact on quality, efficiency, cost, safety, and innovation.

The Role of Precision in Quality Assurance

Precision is paramount in metal fabrication because it directly affects the quality of the final product. High precision ensures that each component meets the specified dimensions and tolerances, which is crucial for the proper functioning of the assembled product. For instance, in the automotive industry, even a slight deviation in the dimensions of a part can lead to significant issues in the vehicle's performance and safety.

Ensuring precision in fabrication helps in maintaining the structural integrity and reliability of the product. It minimizes the risk of defects and failures, thereby enhancing the overall quality and lifespan of the product. This level of quality assurance is vital in industries such as aerospace, where the safety and performance of the final product are non-negotiable.

Enhancing Efficiency and Reducing Waste

Precision in metal fabrication is also critical for enhancing efficiency and reducing waste. Accurate measurements and precise cutting, bending, and welding processes mean that materials are used optimally, minimizing scrap and rework. This not only reduces material costs but also shortens production times, as fewer adjustments and corrections are needed during the manufacturing process.

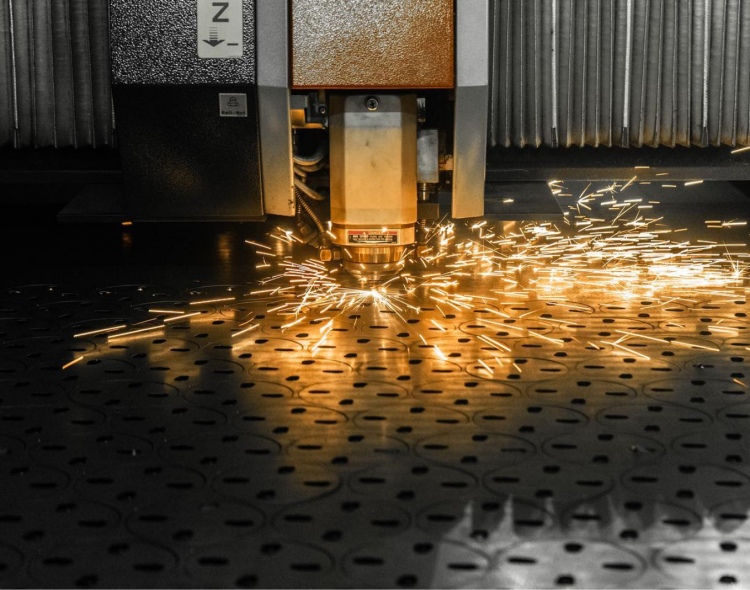

By improving efficiency, companies can meet production deadlines more consistently and reduce operational costs. Precision fabrication tools, such as CNC machines and laser cutters, play a significant role in achieving these efficiency gains by automating processes and ensuring consistent accuracy.

Cost Implications of Precision

While precision in metal fabrication requires an initial investment in high-quality machinery and skilled labor, it ultimately leads to significant cost savings. The reduction in waste and rework directly translates to lower material and labor costs. Additionally, precision fabrication reduces the likelihood of product recalls and warranty claims, which can be extremely costly for manufacturers.

Moreover, precision in fabrication can enhance the company's reputation for quality and reliability, leading to increased customer satisfaction and loyalty. This, in turn, can drive sales and profitability, offsetting the initial costs associated with achieving high precision.

Ensuring Safety and Compliance

In many industries, precision in metal fabrication is not just a matter of quality and cost—it is also a matter of safety and compliance. Products used in critical applications, such as medical devices, construction equipment, and transportation systems, must adhere to stringent safety standards and regulations. Precision fabrication ensures that these products meet all necessary specifications and perform safely under expected conditions.

Failure to maintain precision can result in non-compliance with industry standards, leading to legal penalties and damage to the company's reputation. Therefore, maintaining high precision is essential for ensuring that products are safe for use and meet all regulatory requirements.

Driving Innovation and Competitiveness

Precision in metal fabrication is a key driver of innovation and competitiveness in the manufacturing industry. Advanced fabrication techniques, such as additive manufacturing (3D printing) and laser cutting, rely on precise measurements and control to create complex and intricate designs that were previously impossible or too costly to produce.

By embracing precision fabrication technologies, companies can develop new products with enhanced features and functionalities, giving them a competitive edge in the market. Additionally, the ability to produce high-precision components can open up new business opportunities and markets, further driving growth and success.

Conclusion

Precision in metal fabrication is crucial for ensuring the quality, efficiency, cost-effectiveness, safety, and innovation of manufactured products. As the manufacturing industry continues to evolve, the importance of precision will only grow, driven by the increasing complexity of products and the demand for higher standards of performance and reliability. By investing in precision fabrication technologies and processes, companies can enhance their competitiveness, meet regulatory requirements, and deliver products that exceed customer expectations.