What are the Three Types of Metal Fabrication?

Metal fabrication encompasses various methods used to create metal structures and components customized to specific needs. At Qingdao TianHua YiHe Foundry Factory, we specialize in several types of metal fabrication processes. Let's explore the three main types: Sheet Metal Fabrication, Machining, and Welding.

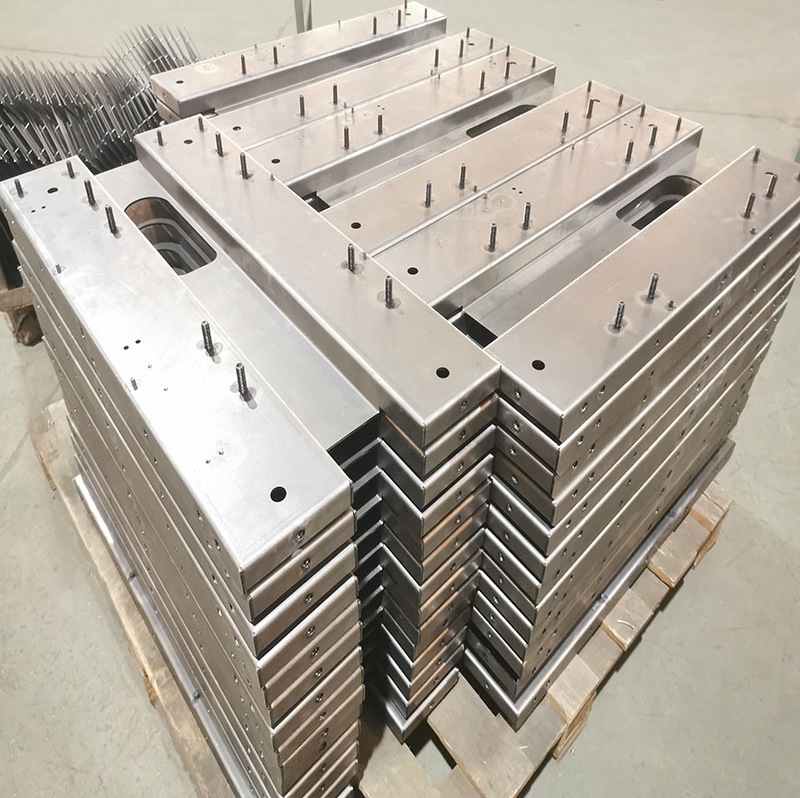

1. Sheet Metal Fabrication

Sheet metal fabrication involves shaping thin sheets of metal into desired forms and structures. This versatile method is widely used in manufacturing industries for creating components with precise dimensions and complex shapes.

1.1. Cutting and Shearing

The process begins with cutting and shearing, where large sheets of metal are cut into smaller sections using tools like shears or laser cutting machines. This step ensures that the metal is prepared for further shaping and forming.

1.2. Forming and Bending

After cutting, the metal sheets undergo forming and bending processes to achieve specific shapes. Techniques such as press braking and roll forming are used to bend the metal without compromising its structural integrity.

1.3. Assembly and Finishing

Once formed, the components are assembled using techniques like welding, riveting, or fastening. Finishing touches such as painting, powder coating, or plating are applied to enhance the appearance and durability of the final product.

1.4. Applications

Sheet metal fabrication is utilized in various industries, including automotive, aerospace, electronics, and construction. It is preferred for its ability to produce lightweight yet durable components with high precision.

2. Machining

Machining is a subtractive manufacturing process that removes material from a workpiece to achieve desired shapes and dimensions. It is used for creating both simple and intricate metal parts.

2.1. Milling

Milling uses rotary cutters to remove material from the surface of a metal workpiece. It is ideal for creating flat surfaces, slots, and complex contours with high precision.

2.2. Turning

Turning rotates a workpiece on a lathe while a cutting tool removes material to form cylindrical shapes. It is used for producing shafts, rods, and other cylindrical components.

2.3. Drilling and Tapping

Drilling creates holes in metal using a rotating drill bit, while tapping adds internal threads to the holes for fasteners. These processes are essential for assembly and installation.

2.4. Applications

Machining is crucial in industries such as manufacturing, aerospace, and medical equipment production. It provides versatility in creating custom components with tight tolerances and intricate designs.

3. Welding

Welding joins metal parts together by melting and fusing them using heat and pressure. It is a fundamental process in metal fabrication for creating strong and permanent connections.

3.1. Arc Welding

Arc welding uses an electric arc to create intense heat, melting the base metals and forming a weld pool. Common types include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding. Each type offers specific benefits depending on the material and application requirements.

3.2. Resistance Welding

Resistance welding uses electrical resistance to generate heat at the joint, bonding the metals together. Spot welding and seam welding are examples used for joining sheet metals.

3.3. Gas Welding

Gas welding involves using a flame to melt and join metals. It is versatile and suitable for both ferrous and non-ferrous metals, commonly used in repair and maintenance applications.

3.4. TIG Welding

TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode to create the weld. It produces high-quality welds and is suitable for thin materials and intricate joints requiring precision.

3.5. Applications

Welding is essential in industries like construction, automotive manufacturing, and shipbuilding. It is used to fabricate structures, frames, pipelines, and other critical components requiring strong, durable connections.

At Qingdao TianHua YiHe Foundry Factory, we leverage our expertise in these metal fabrication techniques to deliver customized solutions that meet the highest standards of quality and precision. Whether it's sheet metal fabrication, machining, or welding, our commitment to excellence ensures that each project is completed to the satisfaction of our clients across various industries.