What is the Metal Fabrication Method?

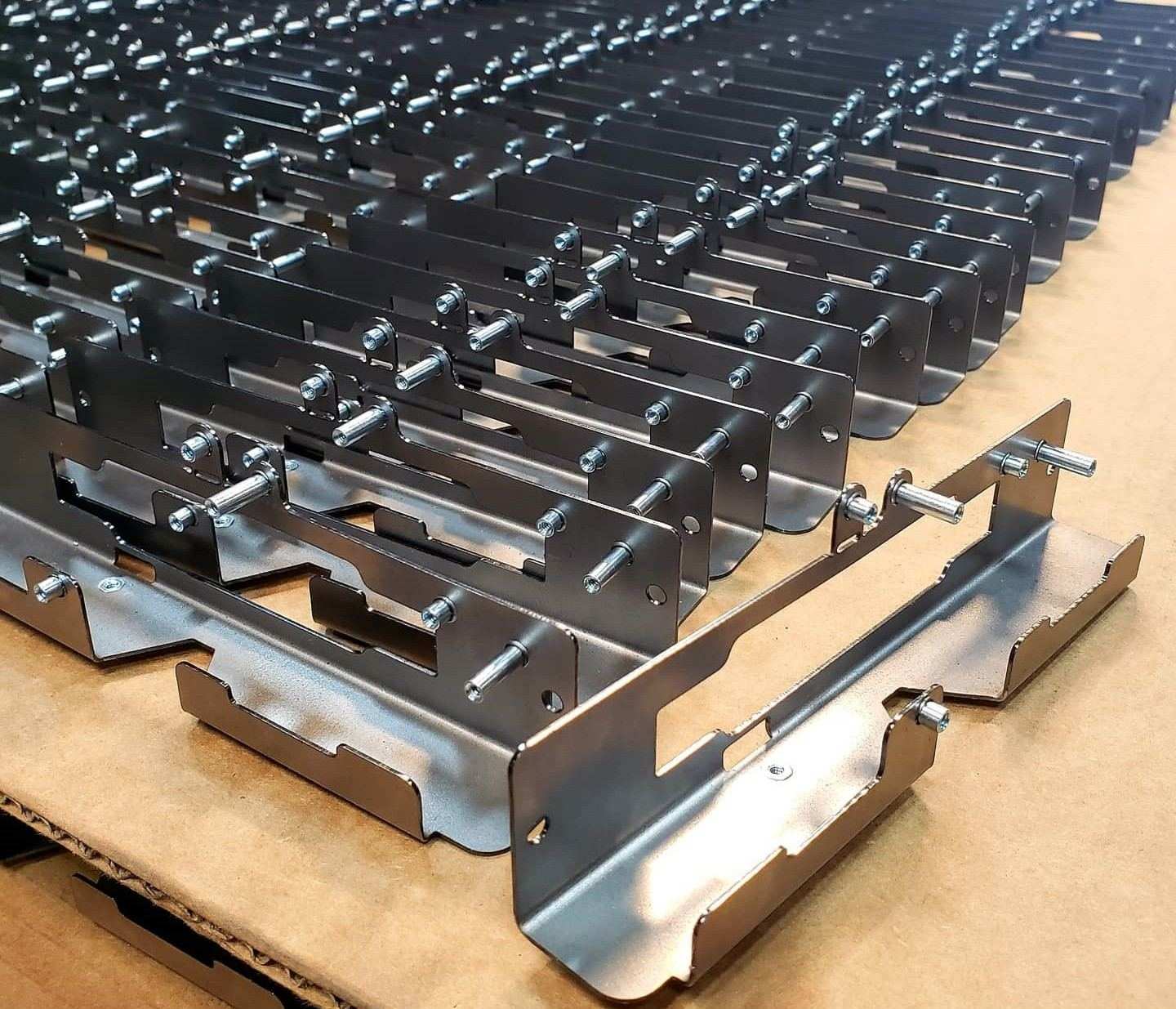

Metal fabrication refers to the process of creating metal structures and components using various techniques. At Qingdao TianHua YiHe Foundry Factory, we employ advanced methods to deliver high-quality metal fabrication services. Let's explore the key methods used in metal fabrication.

1. Cutting Techniques

Cutting is a fundamental step in metal fabrication, where raw metal is shaped into desired forms. Different cutting methods are employed based on project requirements.

1.1. Laser Cutting

Laser cutting utilizes a high-powered laser to cut precise shapes from metal sheets. It is known for its accuracy and ability to handle intricate designs. Laser cutting is crucial for industries requiring high precision.

1.2. Plasma Cutting

Plasma cutting involves using a jet of ionized gas to cut through metal. This method is efficient for cutting thick materials and offers fast cutting speeds, making it suitable for industrial applications where speed is essential.

1.3. Water Jet Cutting

Water jet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through metal. It is suitable for materials sensitive to heat and produces clean edges. Water jet cutting is versatile and used in industries requiring intricate cutting without heat-affected zones.

2. Forming Methods

Forming processes shape metal without removing material. Various techniques are used to achieve specific shapes and dimensions.

2.1. Bending

Bending involves deforming metal using a press brake to create angles or curves. It is used in manufacturing metal components like brackets and enclosures. Bending techniques vary based on the material's thickness and bend radius requirements.

2.2. Rolling

Rolling passes metal through rollers to reduce thickness or create cylindrical shapes. It is essential for producing tubes, pipes, and structural components. Rolling methods include cold rolling for precise thickness control and hot rolling for shaping thick metal plates.

2.3. Stamping

Stamping presses a die into metal sheets to create shapes and patterns. This method is ideal for mass-producing parts with consistent quality. Stamping is used in automotive, aerospace, and consumer electronics industries for creating intricate and uniform parts.

3. Joining Techniques

Joining methods assemble metal components into a cohesive structure. These techniques ensure strong and durable connections.

3.1. Welding

Welding fuses metal parts together using heat and pressure. Techniques like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding are used to join metals of varying thicknesses and compositions. Welding processes are selected based on material properties and joint requirements.

3.2. Riveting

Riveting uses rivets to join metal pieces by deforming the fastener. It is commonly used in industries where disassembly may be required, like aerospace and automotive manufacturing. Riveting ensures robust joints and is suitable for structural applications requiring high load-bearing capacity.

3.3. Brazing and Soldering

Brazing and soldering use filler metals to join metals without melting the base materials. These methods are suitable for delicate assemblies and heat-sensitive materials. Brazing provides strong joints with minimal distortion, while soldering is used for electronics and plumbing applications.

4. Machining Processes

Machining removes material from metal workpieces to achieve precise shapes and sizes. These processes are crucial for creating intricate components.

4.1. Milling

Milling uses rotary cutters to remove material from metal. It is versatile and used to create flat surfaces, slots, and complex shapes. Milling operations include face milling, end milling, and profile milling to meet specific dimensional and surface finish requirements.

4.2. Turning

Turning rotates a workpiece on a lathe while a cutting tool removes material. It produces cylindrical shapes such as shafts and bushings. Turning operations include external turning, internal turning, and facing operations to produce precise diameters and lengths.

4.3. Drilling

Drilling creates holes in metal using a rotating drill bit. It is essential for component assembly and installation. Drilling operations include twist drilling, counterboring, and countersinking to accommodate fasteners and fittings.

5. Finishing Processes

Finishing enhances the appearance and durability of metal products. These processes provide protective coatings and improve surface quality.

5.1. Painting and Coating

Painting and coating apply protective layers to metal surfaces to prevent corrosion and improve aesthetics. They are essential for outdoor applications and decorative finishes. Painting processes include primer coating, base coating, and topcoat application to achieve desired colors and durability.

5.2. Polishing

Polishing smooths and shines metal surfaces to enhance appearance and remove imperfections. It is used for decorative items and high-end applications. Polishing techniques include mechanical polishing, electrochemical polishing, and abrasive polishing to achieve mirror-like finishes and smooth surfaces.

5.3. Sandblasting

Sandblasting uses abrasive materials to clean and texture metal surfaces. It prepares surfaces for coatings and removes contaminants. Sandblasting techniques include bead blasting, shot blasting, and grit blasting to achieve desired surface profiles and cleanliness levels.

At Qingdao TianHua YiHe Foundry Factory, we specialize in these metal fabrication methods to ensure precision and quality in every project. Our expertise and commitment to excellence allow us to meet the diverse needs of industries such as construction, automotive, and manufacturing.