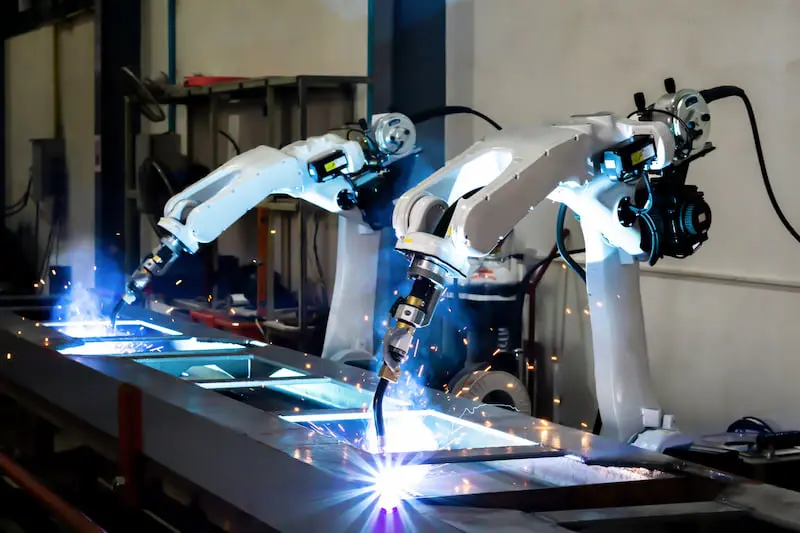

welding and assembly services in sheet metal fabrication industries are critical processes that involve joining various cut, bent, or formed metal parts to create the final product or structure. these services play a pivotal role in ensuring the strength, integrity, and functionality of the end product. here’s a detailed explanation of welding and assembly services:

welding services:

types of welding: there are various welding techniques used in sheet metal fabrication, including tig (tungsten inert gas) welding, mig (metal inert gas) welding, spot welding, and seam welding. the choice of welding technique depends on the material, thickness, and desired aesthetic and functional properties of the joint.

welding preparation: before welding, the metal surfaces must be cleaned to remove any contaminants like oil, grease, or oxide layers that could affect weld quality. additionally, jigs and fixtures are often used to ensure precise alignment of the parts during welding.

welding process: the welding process fuses the metal parts at the molecular level, creating a strong bond. this is achieved by applying heat to the materials, which melts them, allowing them to combine and solidify into a single piece.

quality control: post-welding inspections are conducted to ensure the weld meets the required standards for strength, appearance, and dimensions. non-destructive testing (ndt) methods such as x-ray or ultrasonic testing may be employed to evaluate the internal quality of welds.

finishing: after welding, the area might undergo grinding or polishing to smooth out any irregularities and achieve a finished look.

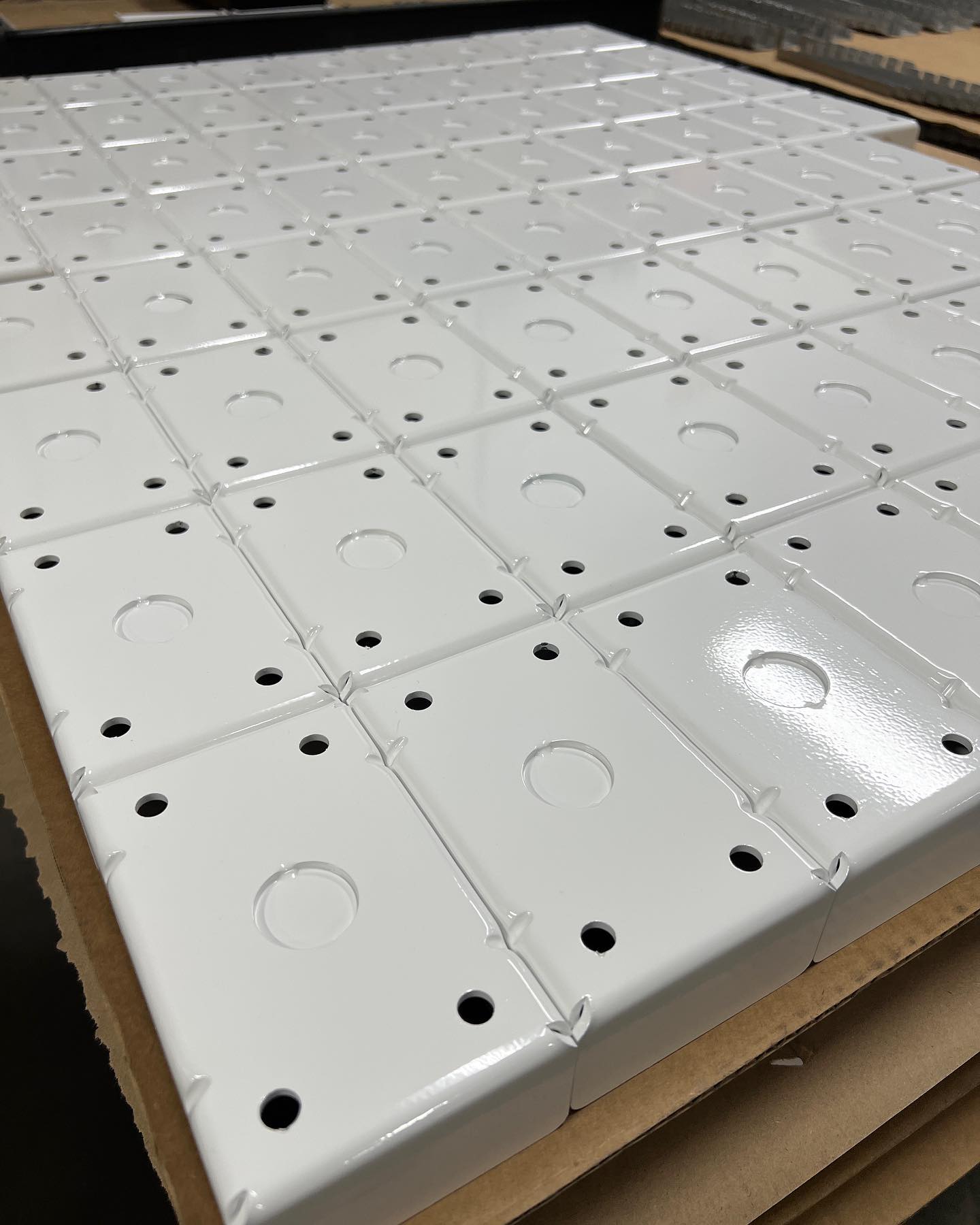

assembly services:

mechanical fastening: in addition to welding, mechanical fasteners like screws, nuts, and bolts are used to assemble sheet metal components. this method allows for disassembly, which can be advantageous for maintenance or replacement purposes.

adhesive bonding: adhesives are also used to bond metal parts where welding is not feasible or desirable. this method provides a uniform stress distribution and can be used for sealing or isolating electrical currents.

alignment and fixturing: accurate alignment of components is crucial during assembly to ensure proper function and fit. fixturing devices and clamps are used to hold parts steady while they are being assembled.

integration of components: sheet metal assemblies often include other elements such as electrical components, insulation, or sealants. integration of these elements requires careful planning and execution to ensure the complete unit functions as designed.

final inspection: once the assembly is complete, it undergoes a final inspection to verify that all elements have been correctly installed and that the product meets the specified performance criteria.

welding and assembly services are vital in transforming individual sheet metal parts into complex structures and systems. they require specialized skills and equipment to ensure the structural integrity and functionality of the final products, which can range from simple enclosures to complex machinery and vehicles.