Utilizing cutting-edge technology like CNC press brakes ensures accuracy and consistency, while quality assurance processes guarantee the bent parts meet the highest standards. Additionally, custom metal bending encourages design innovation, allowing for creative solutions that traditional methods might not provide. Overall, this service is invaluable for industries requiring precision-made metal components for superior functionality and durability.

"Precision Engineered: The Advantages of Custom Metal Bending" delves into the numerous advantages that custom metal bending offers over standardized metal forms. When metal is bent to precise dimensions, it can be integrated seamlessly into complex machinery, architectural structures, and various other applications where accuracy is critical. This level of precision not only ensures a perfect fit but also enhances the overall performance and longevity of the component.

One significant advantage of custom metal bending is the ability to work with a wide range of materials, including steel, aluminum, and copper, each with its unique properties and benefits. This versatility allows designers and engineers to select the most suitable material for their specific application, ensuring optimal strength, durability, and corrosion resistance.

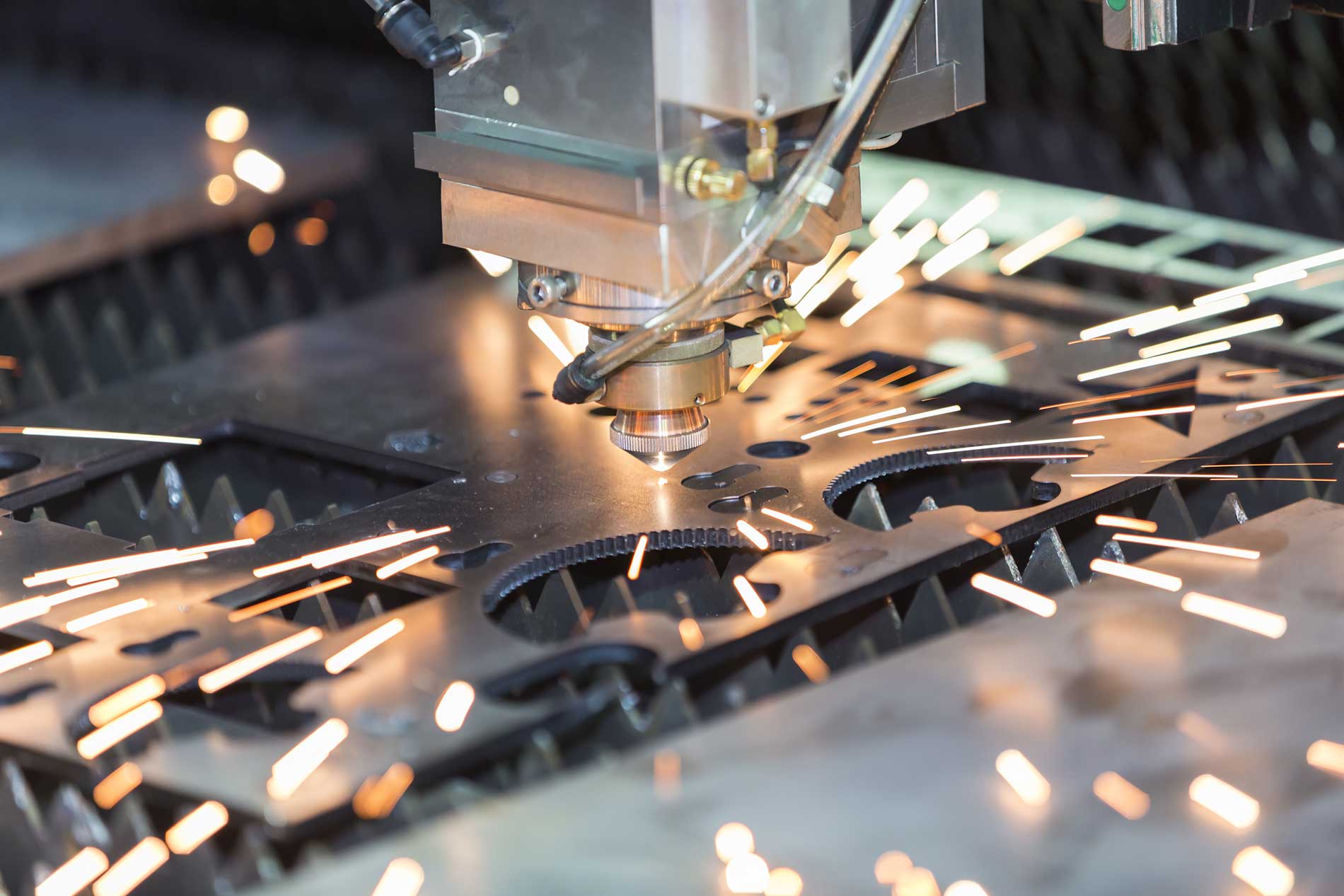

Advanced bending techniques, such as CNC press braking and laser cutting, enable the creation of intricate shapes and angles that would be difficult or impossible to achieve through standard mass-production methods. These techniques also provide a high degree of repeatability, ensuring that each part meets the same exacting standards time after time.

Moreover, custom metal bending services often include comprehensive quality control measures, such as destructive and non-destructive testing, to ensure that each part meets or exceeds industry standards before it leaves the factory. This meticulous approach helps to eliminate potential defects and reduces the need for costly rework or replacements.

In addition to the technical benefits, custom metal bending also provides a competitive edge for businesses. By being able to offer bespoke solutions that precisely meet customer requirements, companies can differentiate themselves in the market and build strong customer relationships based on reliability and innovation.

"Precision Engineered: The Advantages of Custom Metal Bending" highlights how this service offers unparalleled accuracy, design flexibility, and quality assurance, making it an essential process in various industries where metal components are crucial to the success of the end product.