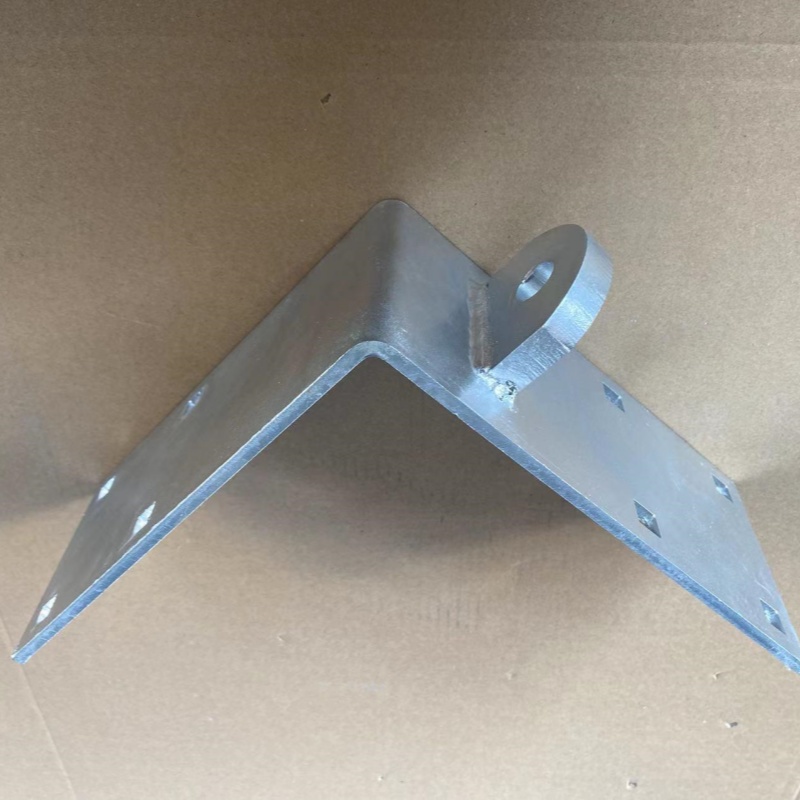

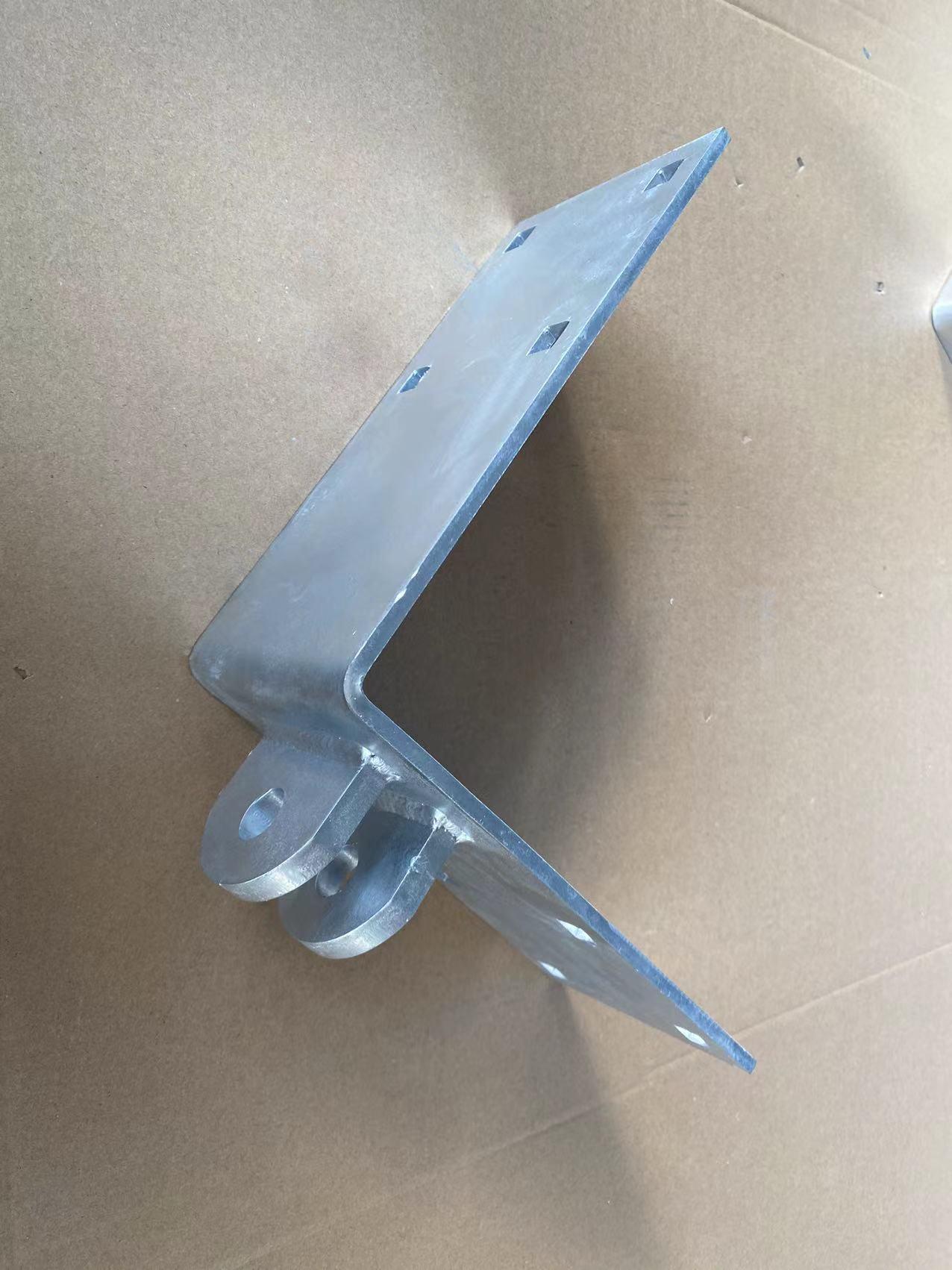

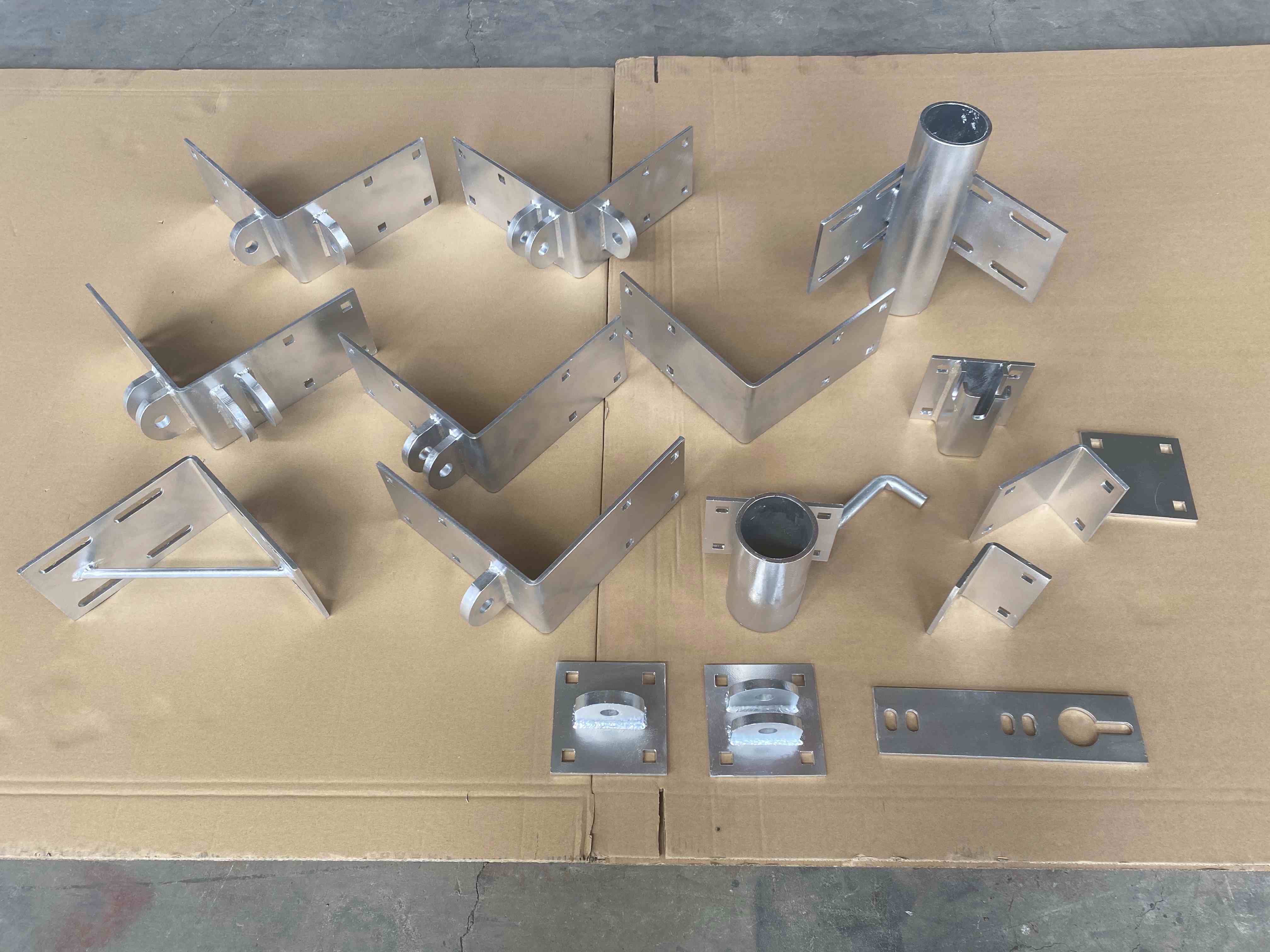

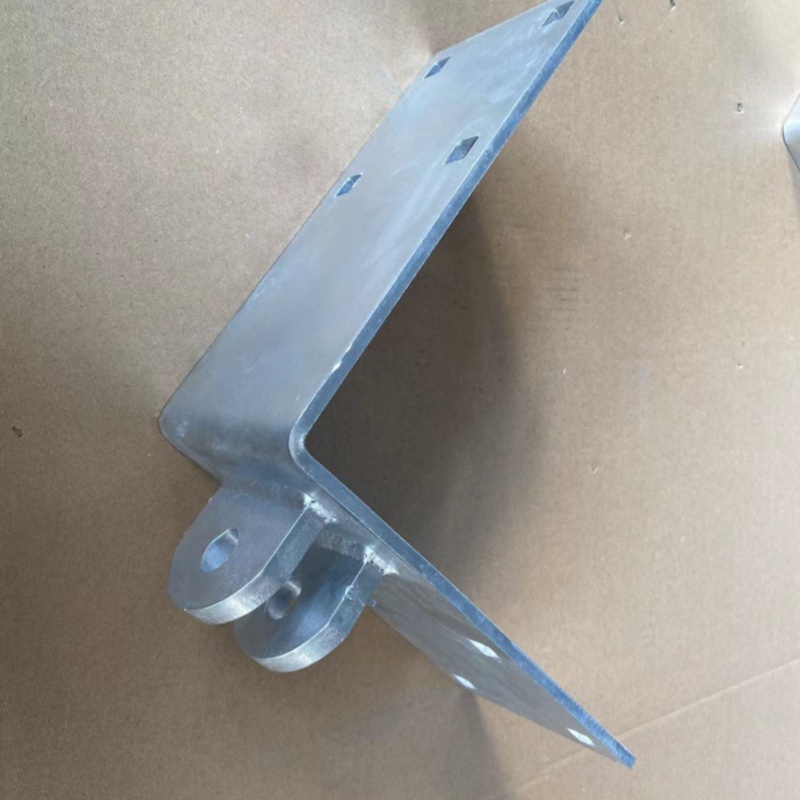

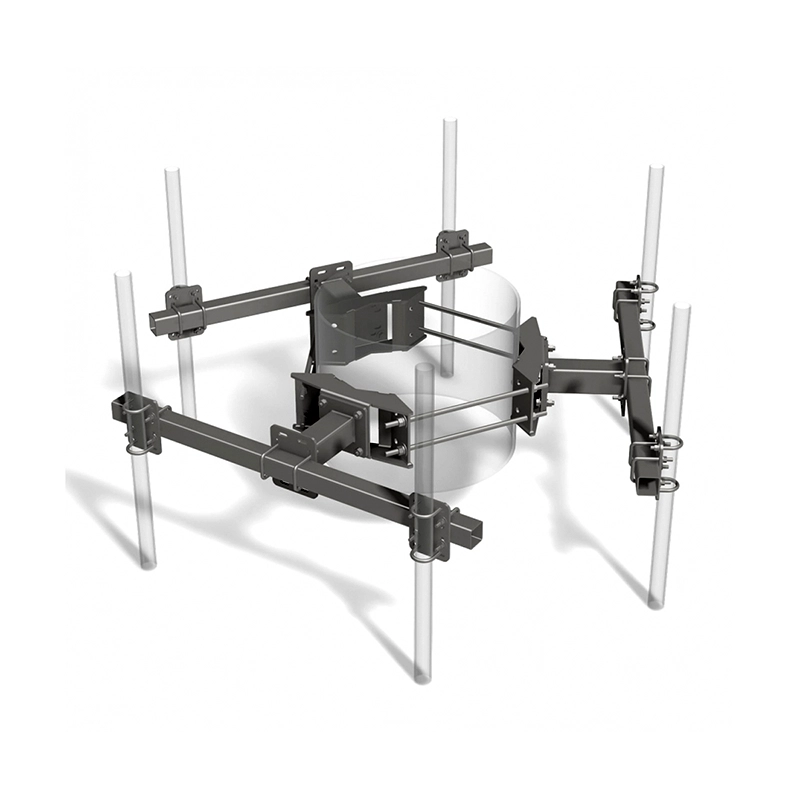

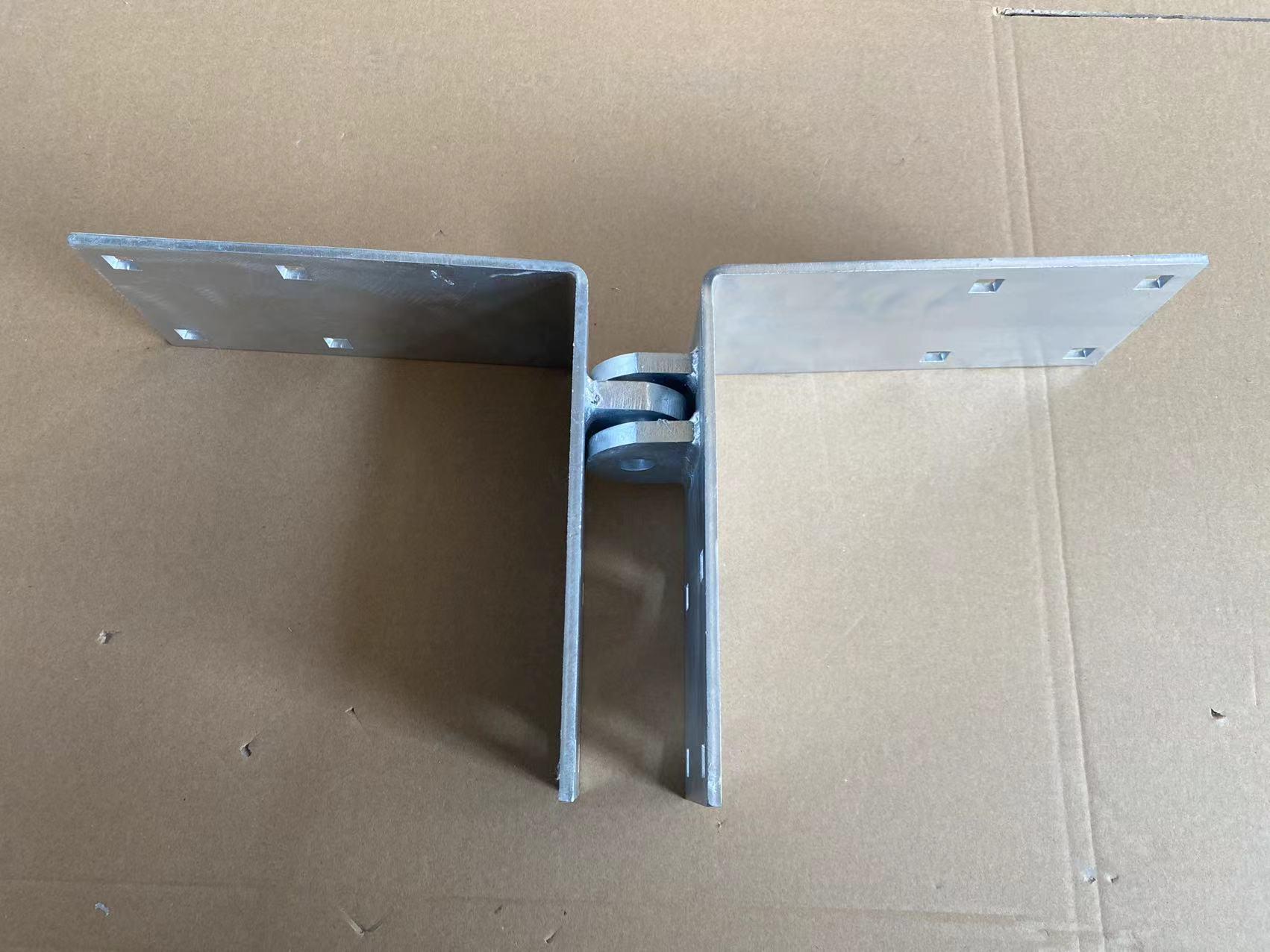

Dock Heavy Duty Female Corner Hardware With HDG Coating

- TianHua YiHe

- CHINA

- One Month

- 10000PCS/Month

Qingdao TianHua YiHe Factory is a professional manufactuer and exporter of high quality marine construction materials. . For wood-framed floating docks, premium hot-dipped galvanized dock framing hardware and wooden gangway hardware ensure a strong, solid, long-lasting floating dock. Likewise, dock mooring hardware and SlideMoor dock brackets provide commercial-grade quality for versatile floating dock mooring solutions.

Heavy-duty female corner hardware with hot dip galvanized (Hot DIP) coating is a specialized component used in dock construction and other heavy-duty applications. This hardware plays a crucial role in connecting and stabilizing structural members, particularly at corners and intersections where high loads and stresses are common. Here is a detailed analysis of their materials, advantages, installation considerations, maintenance, and applications:

Materials and Manufacturing

High-Quality Steel: The core material of heavy-duty female corner hardware is typically high-strength steel, which provides excellent load-bearing capacity and durability.

Hot Dip Galvanization: After fabrication, the hardware is coated with a layer of zinc through the hot dip galvanization process. This involves cleaning the steel, immersing it in a bath of molten zinc, and then allowing it to cool. The zinc coating protects the steel from corrosion, significantly extending its service life.

Stainless Steel Components: Some moving parts or locking mechanisms may be made of stainless steel to prevent rust and ensure smooth operation.

Insulating Layers: In some designs, insulating layers may be added between metal parts to prevent electrical contact and reduce the risk of electrolysis.

Advantages

Corrosion Resistance: The hot dip galvanized coating provides long-lasting protection against corrosion, making it suitable for use in harsh environments such as coastal areas and chemical plants.

Durability: High-strength steel ensures excellent load-bearing capacity and durability, reducing the need for frequent replacements or repairs.

Safety: Properly installed and maintained heavy-duty dock hardware helps ensure the stability and safety of the entire structure.

Ease of Maintenance: Although hot dip galvanized coatings provide excellent protection, they do require less maintenance compared to other protective measures like painting.

Installation Considerations

Surface Preparation: Before installation, the surface where the hardware will be installed must be clean, dry, and free of contaminants to ensure good adhesion.

Correct Alignment: During installation, ensure that all components are correctly aligned to avoid stress concentrations that could lead to failure.

Tightening Torque: Use the correct tightening torque for bolts and nuts to ensure proper preload and avoid overloading.

Professional Installation: It is recommended to have professionals install heavy-duty dock hardware to ensure proper assembly and maximum performance.

Maintenance

Regular Inspections: Periodically inspect the hardware for signs of wear, damage, or corrosion. Address any issues promptly to maintain structural integrity.

Cleaning: Clean the hardware regularly with water or a neutral detergent to remove dirt and salt deposits. Avoid using abrasive cleaners that could damage the zinc coating.

Re-Galvanizing: If the zinc coating is severely damaged, consider re-galvanizing to restore corrosion protection.

Lubrication: Lubricate moving parts periodically with waterproof lubricant to ensure smooth operation and prevent rust.

Applications

Marine and Offshore Structures: Used for reinforcing marine and offshore structures such as docks, piers, and harbor facilities.

Chemical Plants: Suitable for use in chemical plants and other industrial environments prone to chemical splashes or fumes.

Wind Energy Facilities: Used for supporting structures in wind energy facilities, ensuring stability under high wind loads.

Bridges and Overpasses: Used for reinforcing bridges and overpasses, especially those in coastal or corrosive environments.

Heavy-duty female corner hardware with a hot dip galvanized coating offers significant benefits in terms of corrosion resistance, durability, and ease of maintenance. Proper installation and regular maintenance are crucial to maximizing their performance and extending their service life.