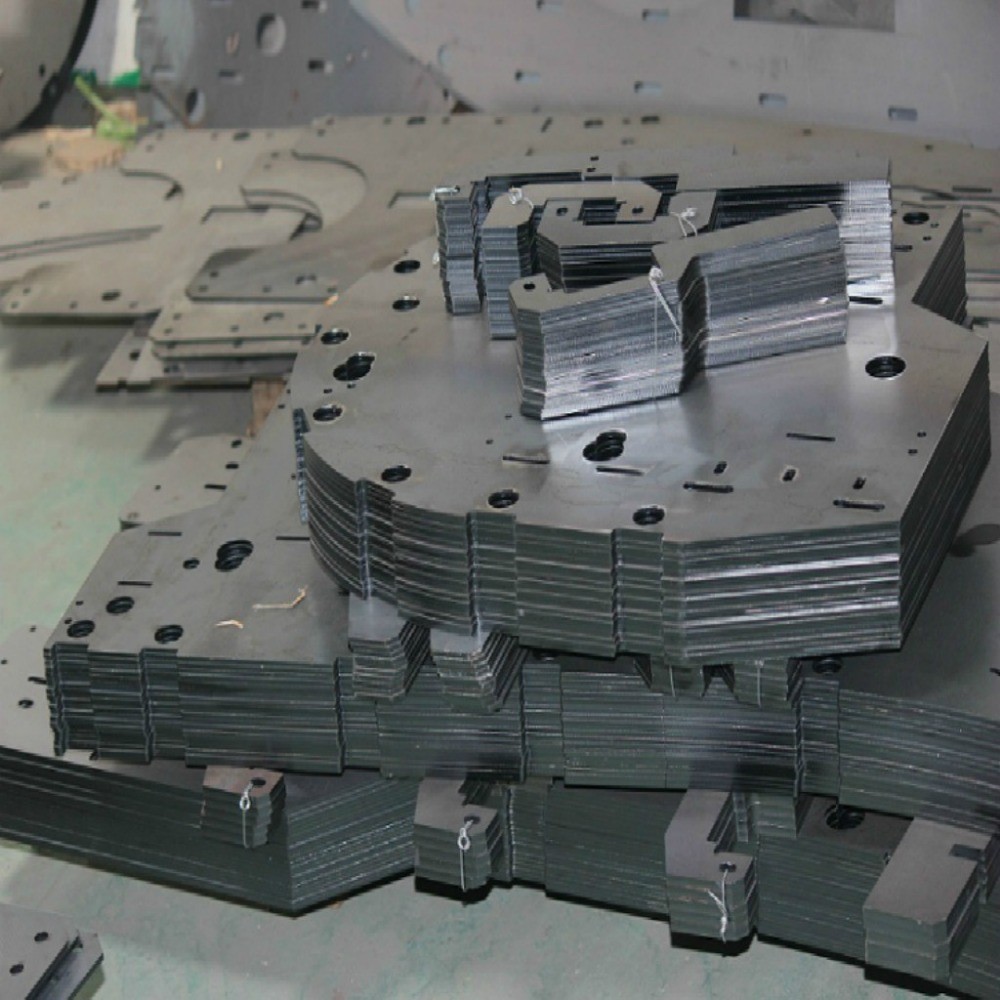

Custom Metal Laser Cutting For Excellence In Manufacturing

- TianHua YiHe

- CHINA

- One Month

- 10000PCS/Month

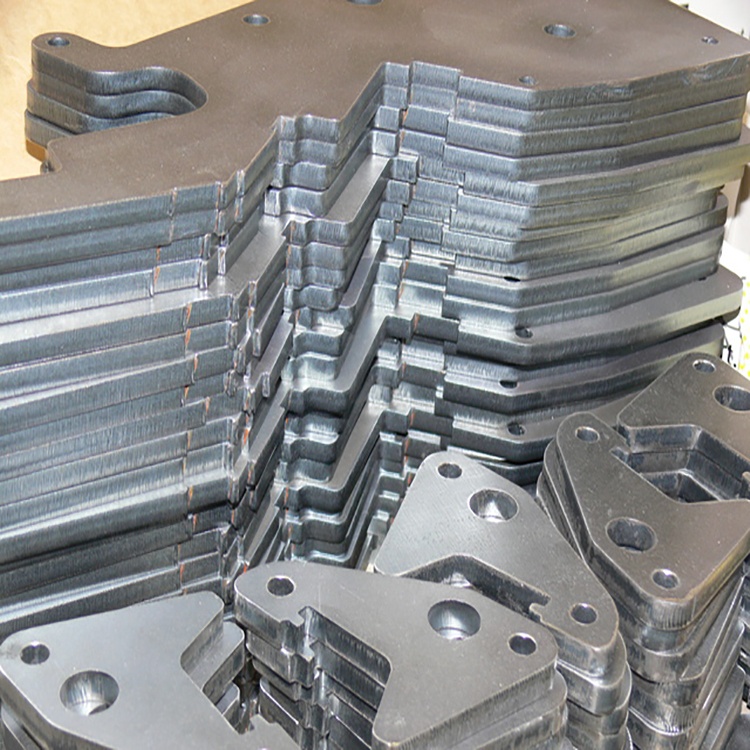

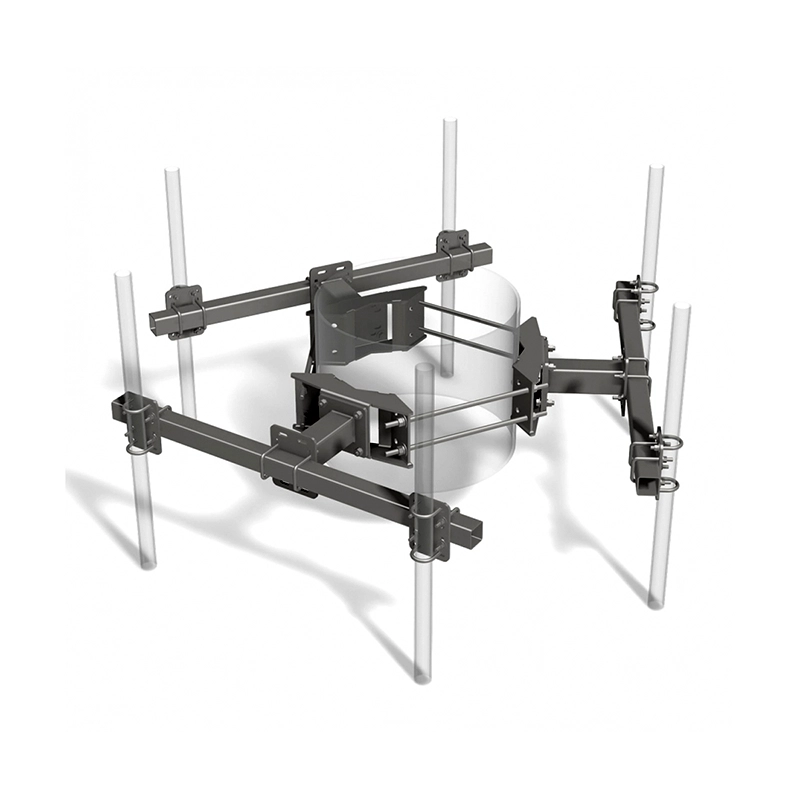

Precision Customized Metal Laser Cutting elevates engineering excellence in manufacturing by enabling the precise and efficient production of metal components. Utilizing advanced laser technology, this method offers unparalleled accuracy, allowing for the creation of complex parts that meet exact design specifications.

The process is suitable for various metals, including steel, aluminum, and titanium, and is ideal for industries such as aerospace, automotive, and electronics. Its minimal thermal impact preserves material integrity, while compatibility with CAD software ensures seamless integration into the manufacturing workflow. By embracing precision customized metal laser cutting, businesses can optimize operations, reduce waste, and deliver products of exceptional quality, strengthening their position in competitive markets.

Precision Customized Metal Laser Cutting stands as a testament to the relentless pursuit of engineering excellence in the realm of modern manufacturing. This sophisticated process harnesses the pinnacle of cutting-edge technology, enabling the production of metal components with unrivaled precision and consistency, thereby redefining traditional manufacturing paradigms.

At the heart of precision customized metal laser cutting lies the advanced laser technology that transcends the limitations inherent to manual or conventional mechanical cutting methods. This technological marvel facilitates the creation of bespoke metal components, ensuring seamless alignment with exacting technical specifications and design criteria. The meticulous control afforded by the laser system guarantees clean, smooth cuts while minimizing thermal impact on the material, thus preserving the structural integrity and superior quality of the end product.

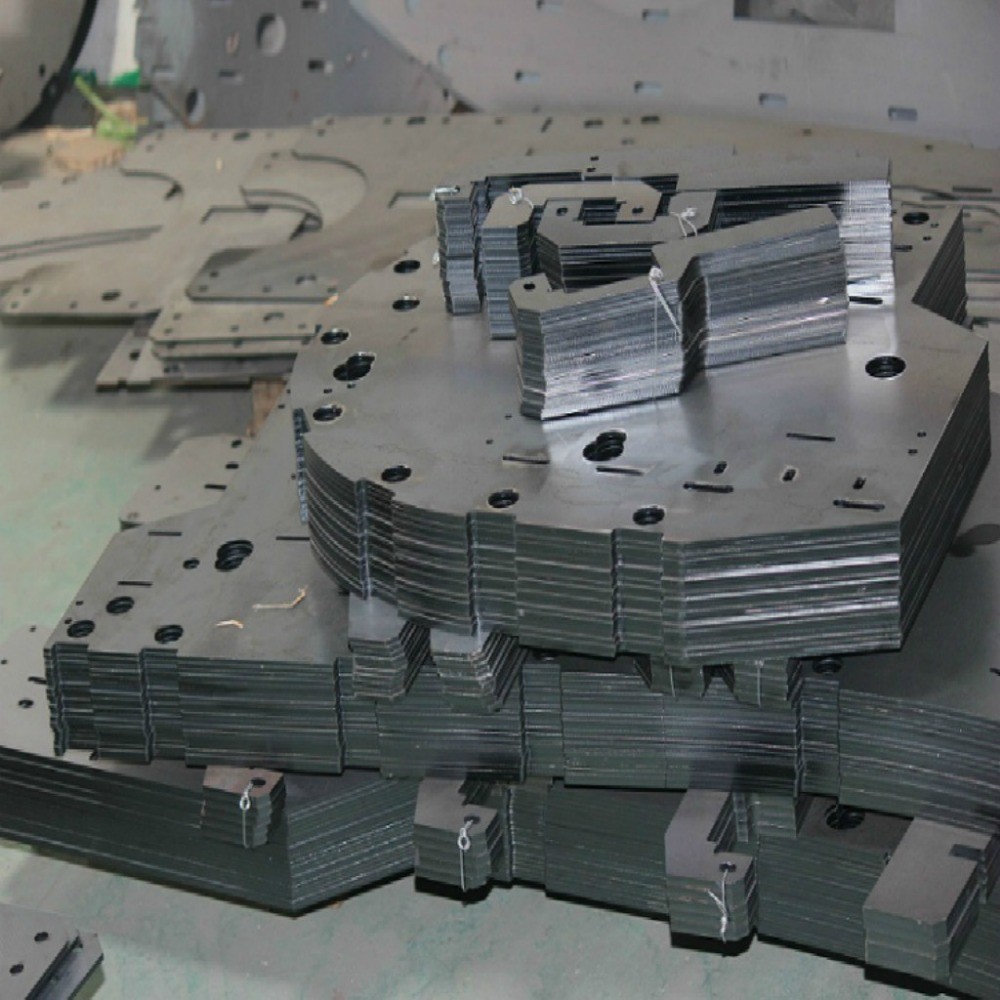

The versatility of precision customized metal laser cutting is truly impressive, extending its capabilities across a wide spectrum of metals including steel, aluminum, brass, and titanium. This adaptability caters to a myriad of applications spanning from the aerospace and automotive industries to the intricate worlds of electronics and medical devices. The precise regulation of the laser's intensity, speed, and focus unlocks the potential for complex patterns and intricate designs to be realized swiftly and proficiently, fostering unprecedented levels of innovation and functional performance.

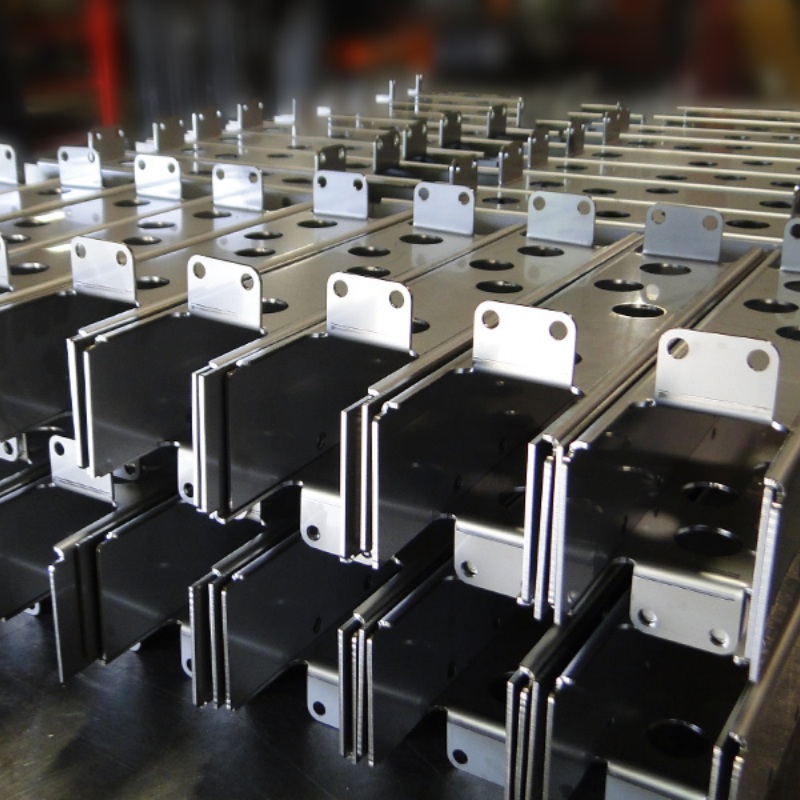

Integrating precision customized metal laser cutting into the manufacturing workflow not only streamlines production processes but also heightens product quality and minimizes material wastage. Its seamless compatibility with computer-aided design (CAD) software further elevates the level of detail and precision, ensuring each part is manufactured to the highest standards of accuracy and consistency.

Businesses that embrace precision customized metal laser cutting empower themselves with a potent tool that excels in product development, optimizes their operations, and delivers unparalleled value to their customers. This commitment to precision and customization secures their leadership position in competitive markets, reinforces their reputation for quality, and paves the way for continued innovation and success.

Precision Customized Metal Laser Cutting is more than just a technique; it is a symbol of engineering excellence and a beacon of innovation in the ever-evolving landscape of manufacturing.