Custom Sheet Metal Manufacturing For Your Project

- TianHua YiHe

- CHINA

- One Month

Custom Sheet Metal Manufacturing from a professional metal fabrication factory offers tailored solutions for your project requirements. Experts in the field provide personalized consultations to understand and translate your specific needs—such as dimensions, tolerances, and material types—into precision-engineered sheet metal components.

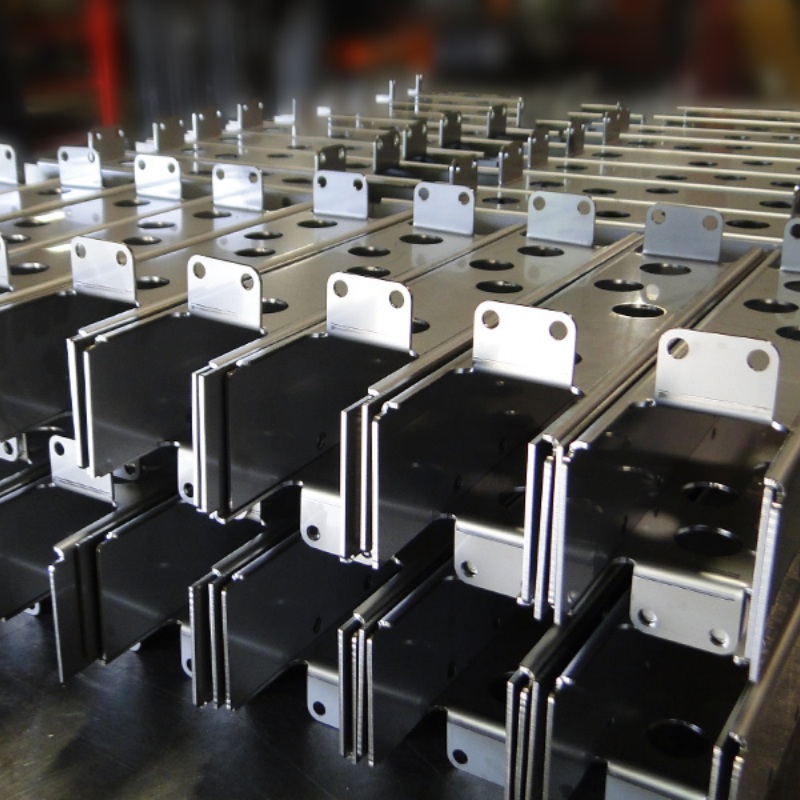

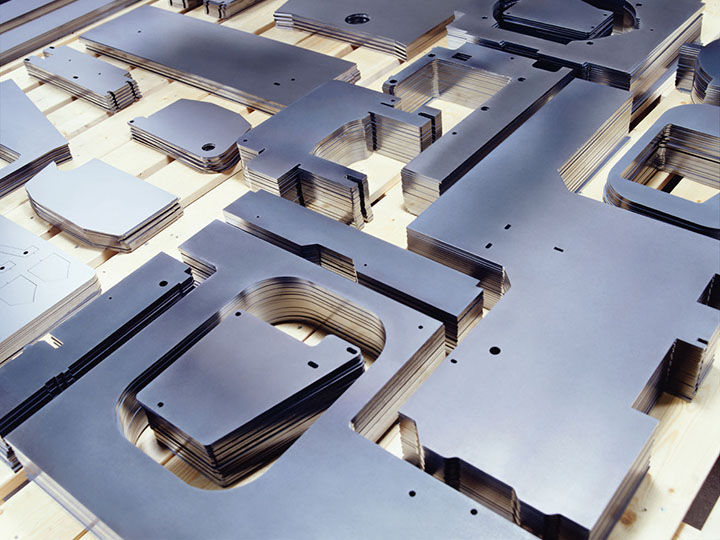

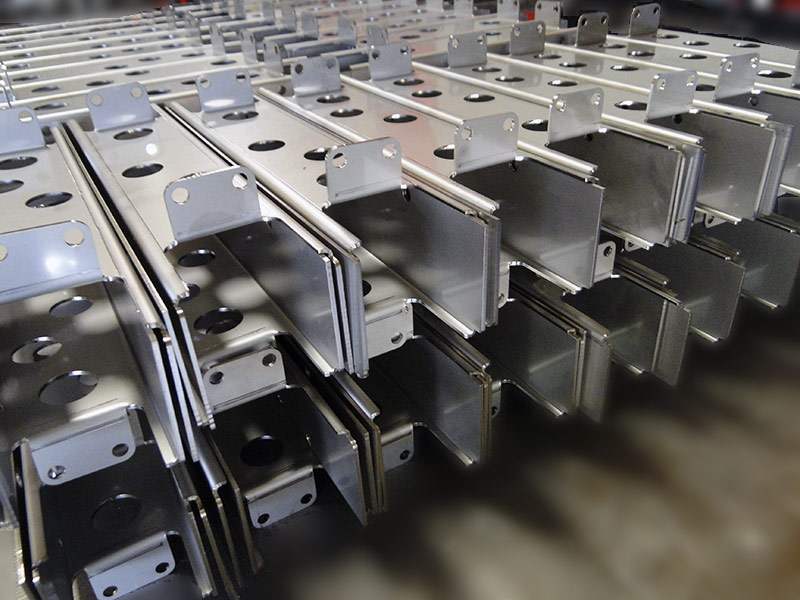

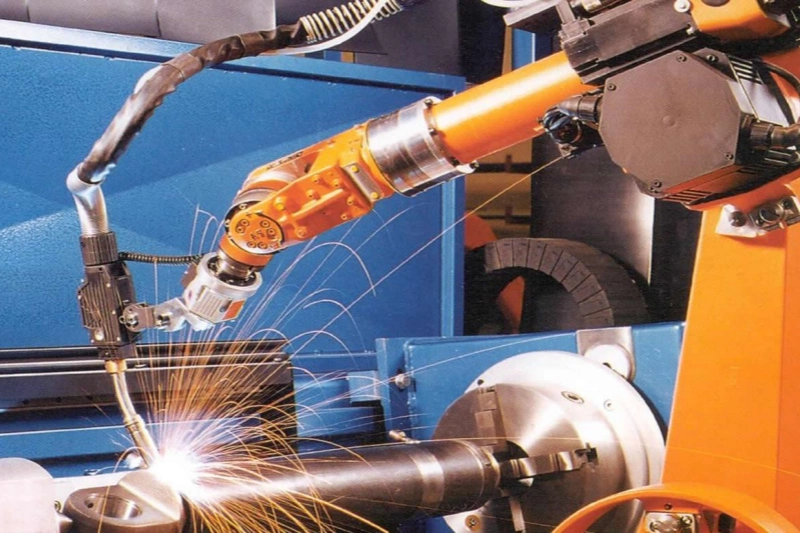

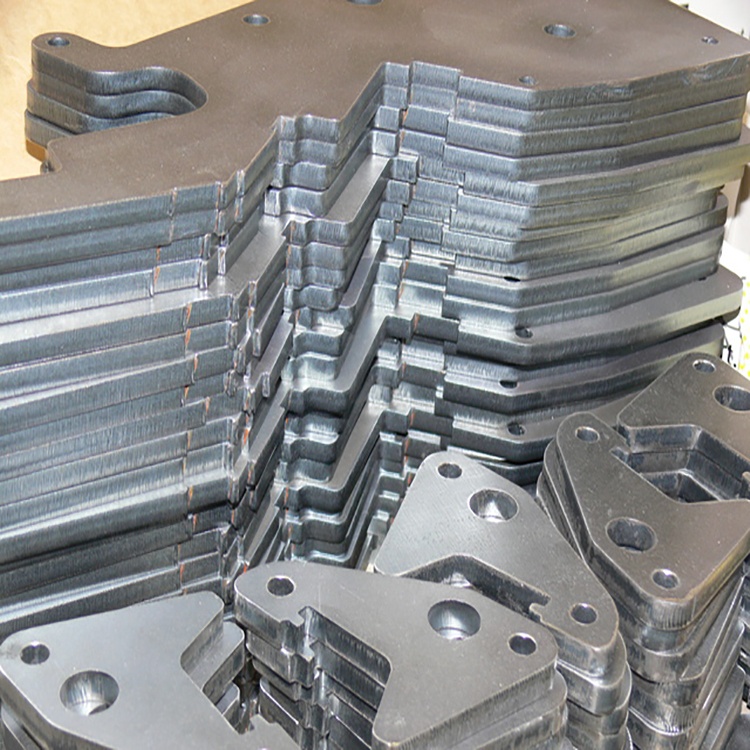

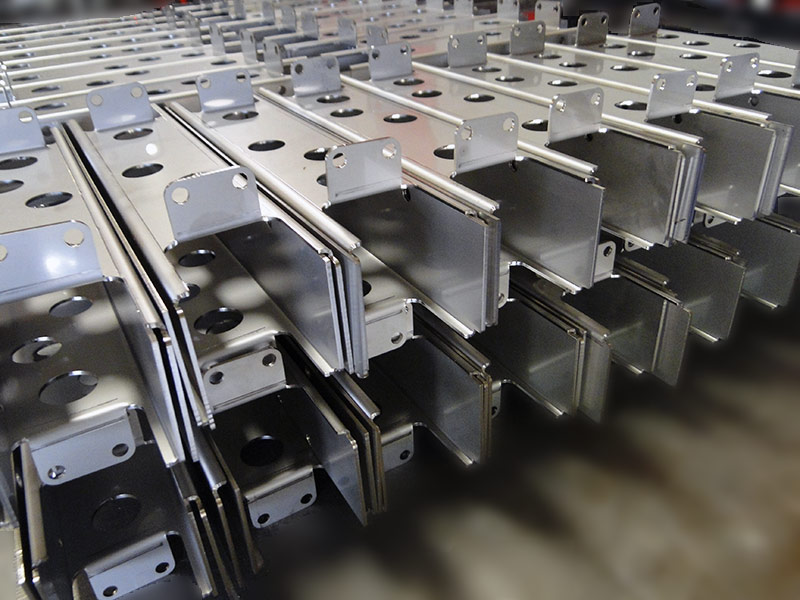

Using cutting-edge technology like laser cutting and CNC punching for accuracy, combined with press brake bending and welding for form and strength, these factories manufacture parts with exacting specifications. They also offer finishing services including deburring, powder coating, and electroplating to enhance durability and appearance.

Rigorous quality control measures are integral throughout the process, ensuring products meet the highest standards before being carefully packaged and shipped directly to you. With a professional metal fabrication factory, you benefit from expert craftsmanship, reliable delivery, and unparalleled support for your custom sheet metal needs.

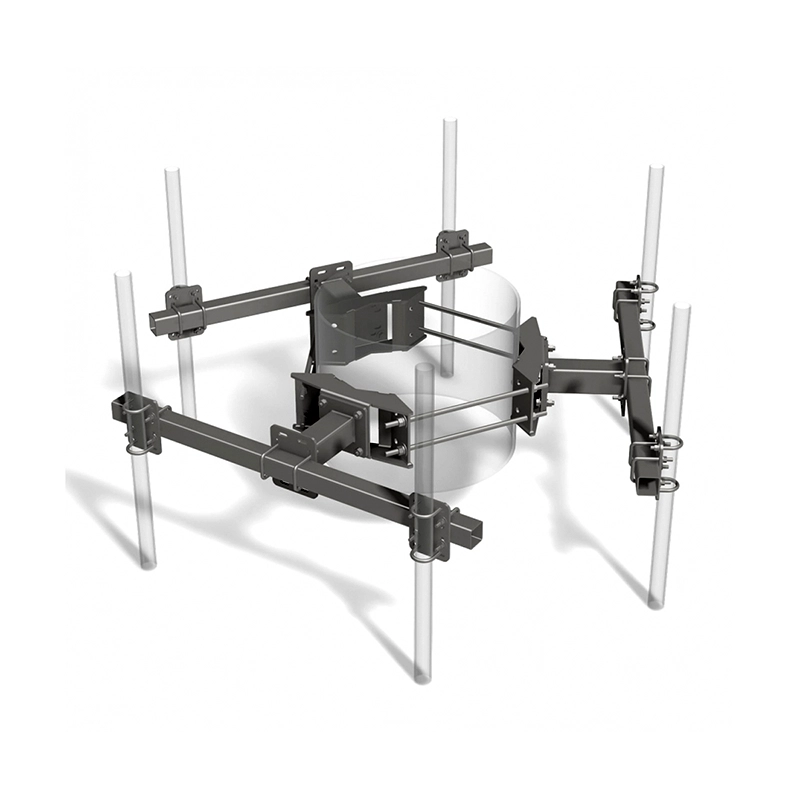

Custom Sheet Metal Manufacturing for your project is a specialized process that transforms flat metal sheets into precision-engineered components, customized to fit the specific needs and dimensions of your unique project. This bespoke manufacturing service is critical in various sectors such as automotive, construction, industrial equipment, and many more where the accuracy and durability of metal parts are essential.

The manufacturing process includes several key steps:

Consultation and Design: The process begins with an in-depth consultation to understand your project requirements thoroughly. This covers details such as the desired functionality, dimensions, tolerances, and any particular aesthetics you need. Using this information, our engineers create precise designs and 3D models, ensuring every detail is exactly to your specifications before beginning manufacturing.

Material Selection: We source high-quality materials based on your requirements. Whether you need stainless steel for corrosion resistance, aluminum for lightweight strength, or cold-rolled steel for structural integrity, we ensure the materials meet your project needs and budget.

Cutting and Shaping: We utilize advanced cutting techniques like laser and CNC punching to achieve precise sizes and shapes. Our forming processes, which include press brake operations, rolling, and welding, further shape the metal to its final form, ensuring it meets the required geometry and strength.

Finishing: Once formed, the sheet metal parts undergo rigorous finishing processes. These may include deburring to remove sharp edges, sandblasting and powder coating to enhance appearance and longevity, and electroplating to improve corrosion resistance.

Quality Assurance: Quality inspections and testing are integral at every stage of production. From material inspection to final product delivery, our stringent quality control measures ensure that each part is manufactured to the highest standards and precisely matches the original specifications.

Assembly and Shipping: For projects requiring assembly, we combine fabricated components into complete units at our facility, streamlining your process. We package each custom component with great care to ensure it reaches you in perfect condition. Our logistics team ensures timely and secure shipping, whether across the city or internationally.

Customer Service: Our commitment to customer service extends beyond the delivery of your order. We pride ourselves on providing ongoing support, answering any queries or resolving any issues that may arise after your custom sheet metal parts have been delivered.

In summary, our custom sheet metal manufacturing service is a comprehensive solution designed to deliver precision-engineered metal components that meet the specific demands of your project. With a focus on quality, efficiency, and customer satisfaction, we are dedicated to ensuring that your unique requirements are not only met but exceeded.