One-Stop Custom Sheet Metal Fabrication Prodution Services

- TianHua YiHe

We offer comprehensive custom sheet metal fabrication services to exact specifications. Our process includes detailed design and engineering, precise cutting and forming using advanced techniques like laser and CNC, and rigorous quality finishing. We source high-quality materials and execute strict quality control to ensure durable, consis tent results. Assemblies are thoroughly tested before being carefully packaged and promptly shipped. Our team provides continuous support to maintain client satisfaction. With us, you get streamlined, dependable service from a single source, ensuring your projects are delivered on time, every time.

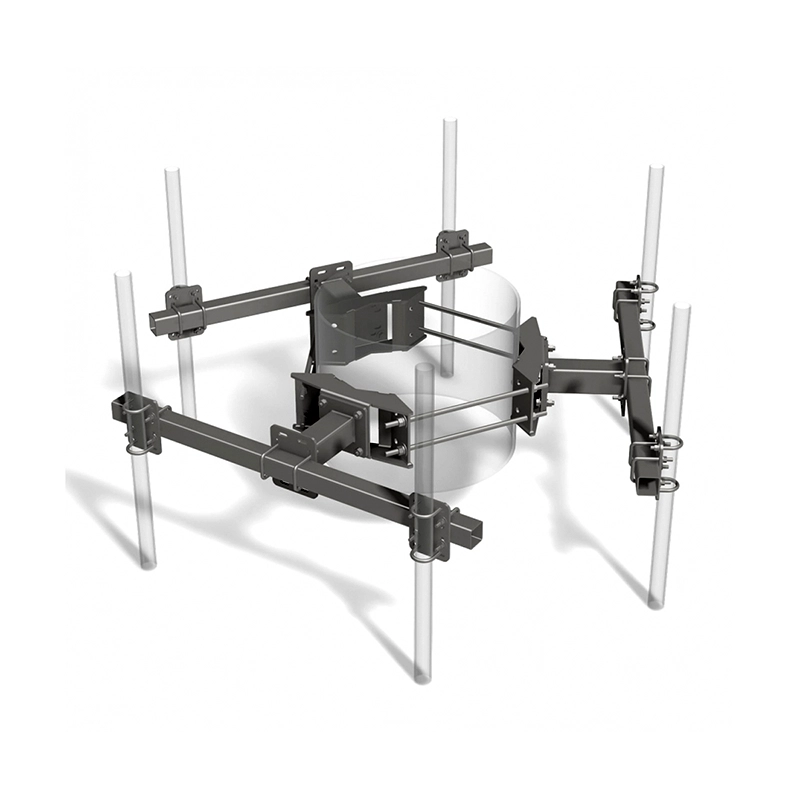

At the forefront of precision engineering and bespoke metalwork, our one-stop custom sheet metal fabrication services stand out as a comprehensive solution for industries ranging from automotive to aerospace, electronics, and beyond. We specialize in transforming flat metal sheets into complex, functional components that meet exacting specifications and withstand the test of time.

Our production process begins with a thorough consultation phase where we understand your unique requirements, design considerations, material preferences, and application needs. This collaborative approach ensures that every detail is accounted for before manufacturing begins.

Design and Engineering:Our state-of-the-art design and engineering team utilizes advanced software to create precise blueprints and 3D models. These detailed plans are then reviewed with clients for approval, ensuring every dimension, bend, and cut meets the project's specific demands.

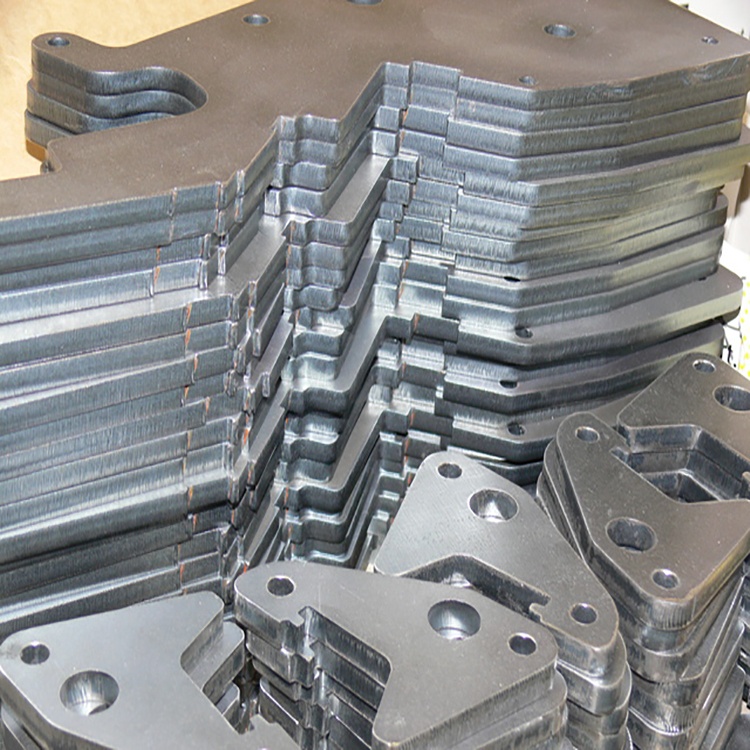

Material Sourcing: We maintain high standards by sourcing only premium quality sheet metal materials, such as stainless steel, aluminum, and cold-rolled steel. Our established supply chain allows us to offer competitive pricing without compromising on material quality.

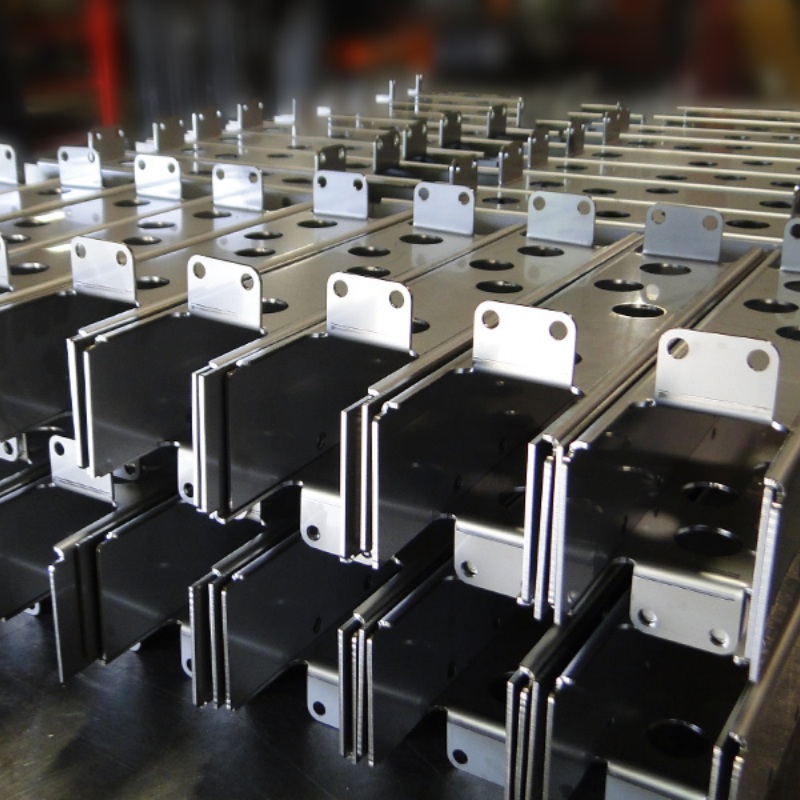

Cutting and Forming:Using cutting-edge technology like laser cutting, CNC punching, and plasma cutting, we achieve precise shapes and sizes. Our forming processes include press brake operations, rolling, and welding to ensure accurate and consistent results every time.

Finishing: Post-fabrication, components undergo rigorous finishing processes including deburring, sandblasting, powder coating, and electroplating. These steps not only enhance aesthetic appeal but also improve corrosion resistance and durability.

Assembly and Inspection:Our assembly capabilities allow us to combine various fabricated parts into complete assemblies, streamlining the process for our clients. Rigorous quality inspections and testing are conducted at each stage to guarantee that the final product aligns with the original specifications and client expectations.

Quality Assurance:Our commitment to excellence is underpinned by a robust quality assurance program. From raw material inspection to final product delivery, we adhere to strict quality control measures to ensure consistency and reliability.

Packaging and Shipping:We take great care in packaging our custom sheet metal products to ensure they reach you damage-free. Our logistics team works efficiently to provide timely delivery, whether across town or around the globe.

Customer Service:Our customer service does not end with the delivery of your order. We pride ourselves on ongoing support and are always available to address any questions or concerns you may have about your custom sheet metal fabrications.

By choosing our one-stop custom sheet metal fabrication services, you benefit from a seamless process that combines expertise, efficiency, and reliability. Your projects will be realized with precision and delivered with confidence, ensuring that your needs are met with the highest level of craftsmanship and service.