Custom Aluminum Sheet Metal Fabrication Supplier

- TianHua YiHe

- CHINA

- One Month

- 10000PCS/Month

"Custom-Aluminum-Sheet-Metal-Fabrication-Realization-Exactness-And-Longevity" refers to the specialized process of manufacturing custom aluminum sheet metal products with a focus on achieving precision and durability. This technique involves an intricate sequence of steps, including design, fabrication, finishing, and quality control, all tailored to fulfill bespoke requirements and specifications.

The emphasis is placed on realizing exact designs while ensuring the longevity of the final product. Expertise in custom aluminum sheet metal fabrication allows for the creation of unique solutions that cater to diverse industrial and consumer needs. The process encompasses cutting-edge technology and skilled craftsmanship to produce components that are not only visually appealing but also functionally superior. It is widely used in various sectors, including construction, automotive, aerospace, and electronics, where accuracy, strength, and long-lasting performance are paramount. By adhering to stringent industrial standards and embracing innovative techniques, custom aluminum sheet metal fabrication ensures that each product is a testament to precision and resilience, standing as a hallmark of quality manufacturing.

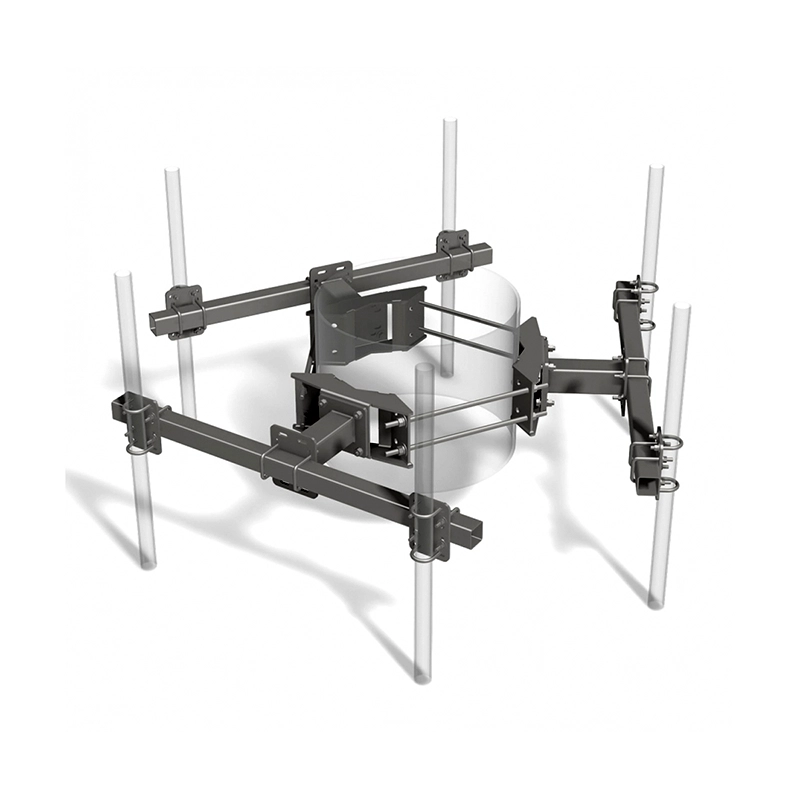

Custom-aluminum-sheet-metal-fabrication-realization-exactness-and-longevity is a specialized manufacturing process that focuses on producing high-quality, customized aluminum sheet metal products. The process involves several key stages, including design, fabrication, finishing, and quality control, all tailored to meet the specific needs and requirements of individual clients.

The first stage of the process involves close collaboration with clients to understand their unique requirements and specifications. This includes detailed discussions about the desired dimensions, shape, tolerances, and other critical parameters of the final product. Based on this input, skilled designers create precise blueprints and 3D models, providing a clear visual representation of the expected outcome.

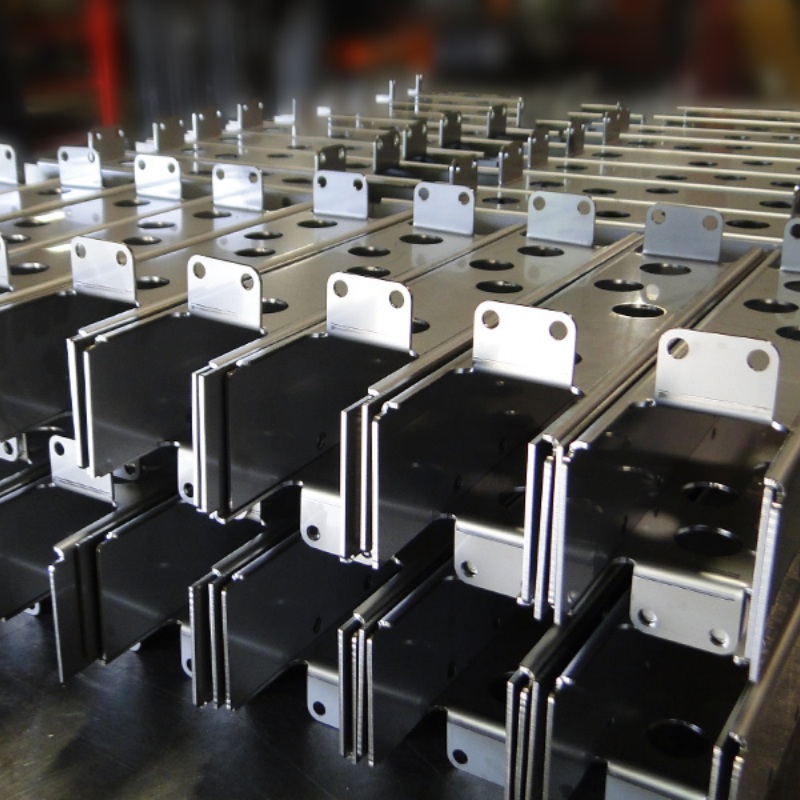

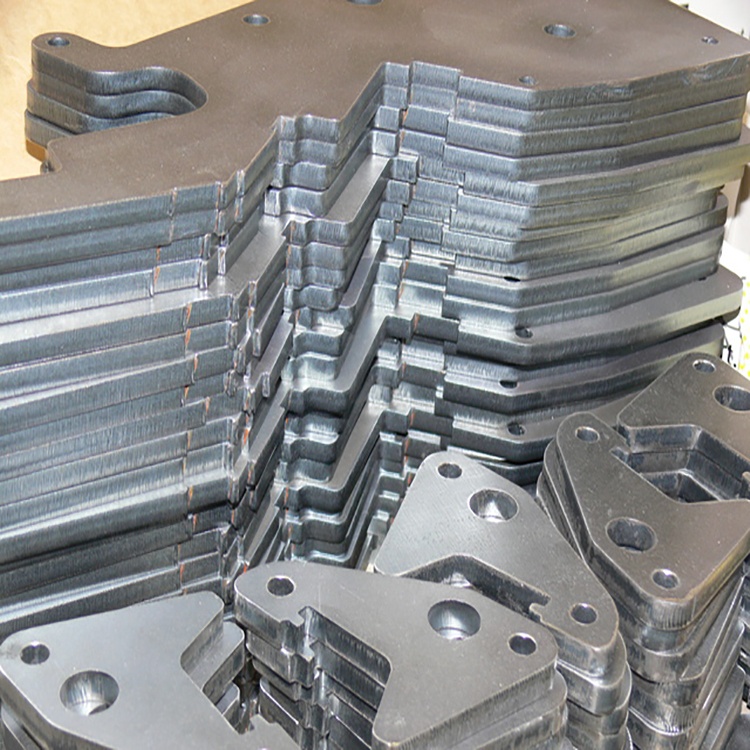

Once the design is finalized, the fabrication stage begins. This involves selecting the appropriate aluminum alloy and preparing it for processing. The aluminum sheet metal is then cut, bent, formed, or otherwise manipulated using advanced machinery and tools to achieve the desired shape and size. Various techniques such as CNC machining, laser cutting, and press braking may be employed to ensure precision and accuracy in the fabrication process.

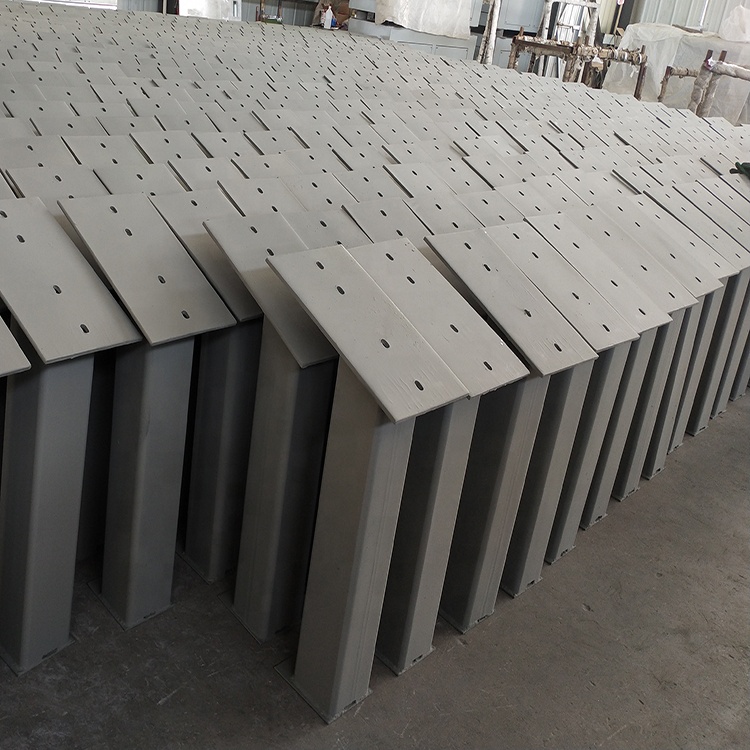

After the initial shaping, the aluminum sheet metal component moves on to the finishing stage. This is where the product receives any necessary surface treatments or coatings to enhance its appearance, durability, and performance. Common finishing techniques include anodizing, powder coating, polishing, and painting, among others. These processes not only improve the aesthetic appeal of the product but also provide a protective layer that increases its resistance to corrosion and wear.

Quality control is an integral part of custom aluminum sheet metal fabrication. Rigorous inspection and testing procedures are implemented at various stages of production to ensure that each product meets the highest standards of excellence. This includes checking dimensions, examining surfaces for defects or imperfections, and verifying that mechanical properties meet specified requirements.

The realization of exactness and longevity in custom aluminum sheet metal fabrication is crucial for numerous industries, including construction, automotive, aerospace, and electronics. Accurate dimensions and precise tolerances are essential for components that must fit seamlessly into larger systems or machines. Longevity is particularly important for applications where the product will be exposed to harsh environments or subjected to rigorous use over extended periods.

In summary, custom-aluminum-sheet-metal-fabrication-realization-exactness-and-longevity encompasses a comprehensive process that combines advanced technology, skilled craftsmanship, and stringent quality control measures to produce bespoke aluminum sheet metal products that meet the exacting standards of today's industrial and commercial sectors. The focus on precision and durability ensures that these products are not only functional but also built to last, making them a wise investment for any application requiring custom metal components.